Glossary

Fiber Optic Cable

(1) A Package for an optical Fiber or fibers that may include cladding, buffering, strength members and an outer jacket. (2) Bundled Glass rods (fibers) that are extremely thin and flexible and are capable of transmitting voice, video, and Data signals in either analog or Digital formats. This is accomplished with very little Loss in signal quality. A single glass fiber can carry the equivalent of 100 channels of television or 100,000 telephone calls, with even more capacity possible by encasing many fibers within a cable.

Fiber optic Cable Functions as a “light guide,” guiding the Light introduced at one end of the cable through to the other end. The Light Source can either be a light-emitting Diode (LED) or a laser.

While fiber Optic Cable itself has become cheaper over time – a equivalent length of copper cable cost less per foot but not in capacity. Fiber Optic Cable Connectors and the equipment needed to install them are still more expensive than their copper counterparts.

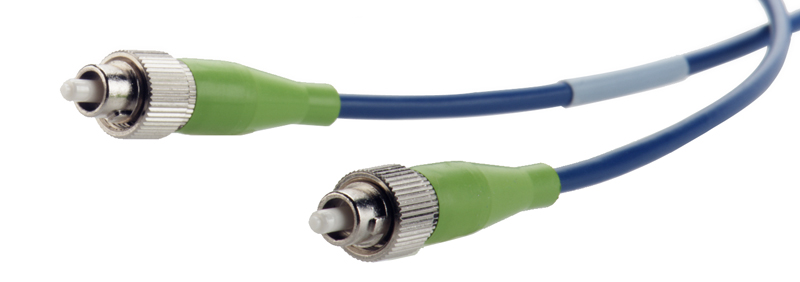

Single Mode cable is a single stand of glass fiber with a diameter of 8.3 to 10 microns that has one mode of transmission. Single Mode fiber, with its relatively narrow diameter, typically has one mode in which it will propagate, 1310 or 1550nm. Singlemode Fiber carries higher Bandwidth than Multimode fiber, but requires a light Source with a narrow spectral width.

Single-mode fiber gives you a higher Transmission rate and up to 50 times more distance than multimode, but it also costs more. Single-mode fiber has a much smaller Core than multimode. The small core and single light-wave virtually eliminate any Distortion that could result from overlapping light pulses, providing the least signal Attenuation and the highest transmission speeds of any Fiber Cable type.

Single-mode Optical Fiber is an optical fiber in which only the lowest order Bound Mode can propagate at the Wavelength of interest typically 1300 to 1320nm.

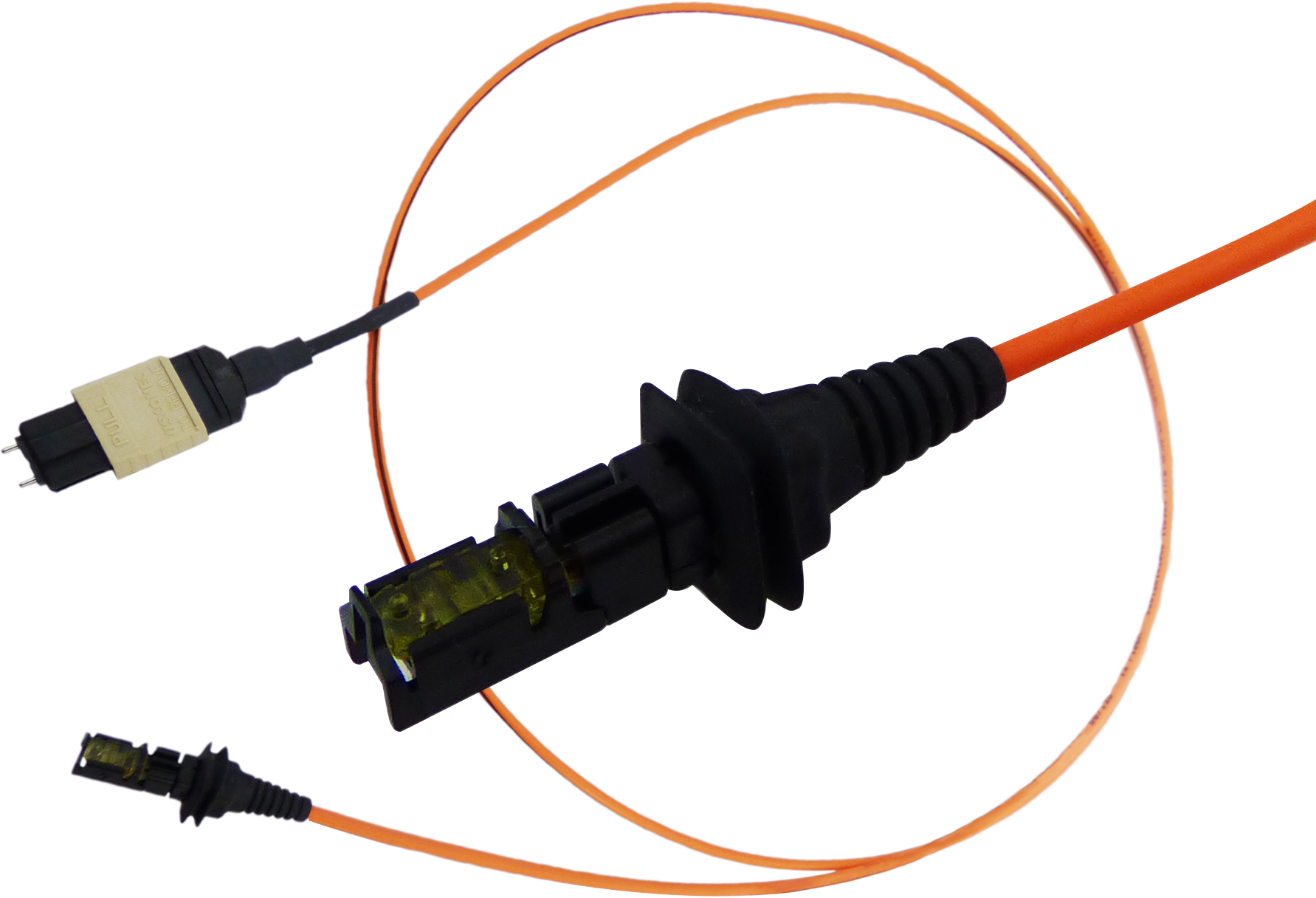

Multimode cable is made of of glass fibers, with a common diameters in the 50-to-100 Micron Range for the light carry component (the most common size is 62.5). POF is a newer plastic-based cable which promises performance similar to glass cable on very short runs, but at a lower cost.

Multimode Fiber gives you high bandwidth at high speeds over medium distances. Light waves are dispersed into numerous paths, or modes, as they travel through the cable’s core typically 850 or 1300nm. Typical multimode Fiber Core diameters are 50, 62.5, and 100 micrometers. However, in long cable runs (greater than 3000 feet , 914.4 meters), multiple paths of light can cause signal distortion at the receiving end, resulting in an unclear and incomplete data transmission.

Plastic core cable is used for short-distance applications, such as airplane wiring and wiring for some buildings.

Silica cable is categorized as either multimode cable, which is used for short-distance connections (LANs, campus networks, and short-distance metro networks), or single-mode cable that is used for long-distance (cross-country networks and intercontinental submarine links). The light source for the former is typically an LED, while the light source for the latter is a laser. Long-haul fiber-optic cable is often bundled with anywhere from 100 to 800 fibers per cable.

In practical fibers, the Cladding is usually coated with a tough resin Buffer layer, which may be further surrounded by a Jacket layer, usually plastic. These layers add strength to the fiber but do not contribute to its optical wave guide properties. Rigid fiber assemblies sometimes put light-absorbing (“dark”) glass between the fibers, to prevent light that leaks out of one fiber from entering another. This reduces cross-talk between the fibers, or reduces flare in fiber Bundle imaging applications.

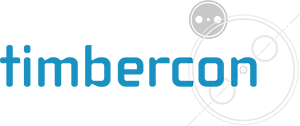

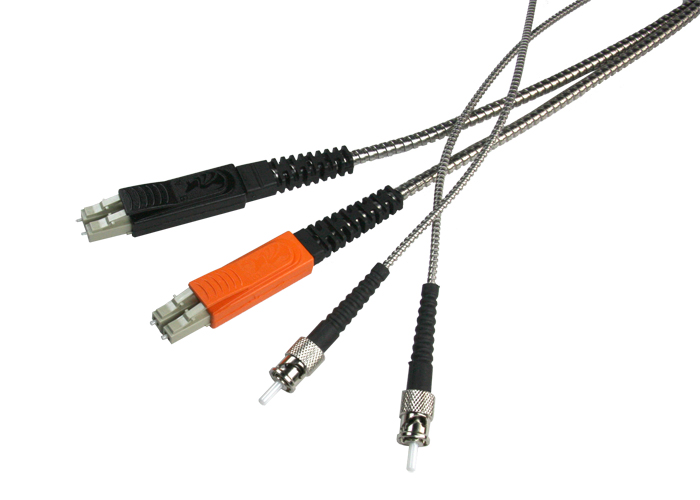

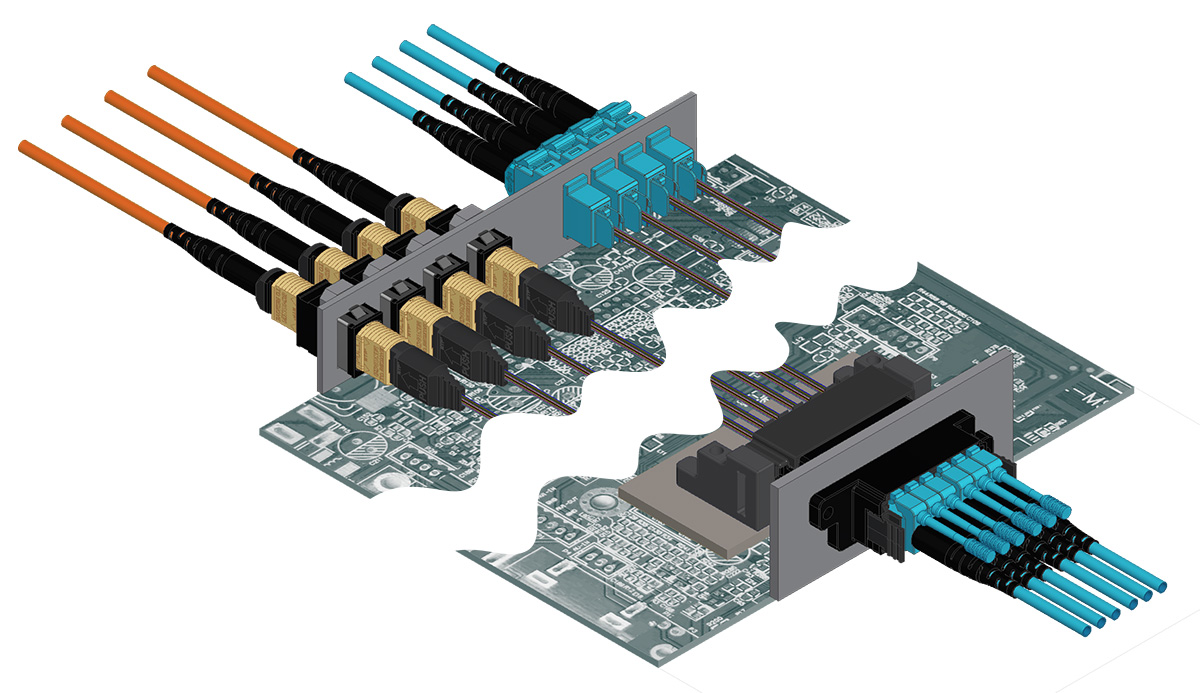

For indoor applications, the jacketed fiber is generally enclosed, with a bundle of flexible fibrous polymer strength members like Aramid (e.g. Twaron or Kevlar), in a lightweight plastic cover to form a simple cable. Each end of the cable may be terminated with a specialized optical fiber Connector to allow it to be easily connected and disconnected from transmitting and receiving equipment.

For use in more strenuous environments, a much more robust cable construction is required. In loose-tube construction the fiber is laid helically into semi-rigid tubes, allowing the cable to stretch without stretching the fiber itself. This protects the fiber from tension during laying and due to temperature changes. Alternatively the fiber may be embedded in a heavy polymer jacket, commonly called “tight buffer” construction. These fiber units are commonly bundled with additional steel strength members, again with a helical twist to allow for stretching.

Finally, the cable may be armored to protect it from environmental hazards, such as construction work or gnawing animals. Undersea Cables are more heavily armored in their near-shore portions to protect them from boat anchors, fishing gear, and even sharks, which may be attracted to the electrical power signals that are carried to power amplifiers or repeaters in the cable.

Modern Fiber Cables can contain up to a thousand fibers in a single cable, SO the performance of optical networks easily accommodates even today’s demands for bandwidth on a Point-to-Point basis. However, unused point-to-point potential bandwidth does not translate to operating profits, and it is estimated that no more than 1% of the optical fiber buried in recent years is actually ‘lit’.

Modern cables come in a wide variety of sheathings and armor, designed for applications such as direct burial in trenches, dual use as power lines, installation in conduit, lashing to aerial telephone poles, submarine installation, or insertion in paved streets. In recent years the cost of small fiber-count pole mounted cables has greatly decreased due to the high Japanese and South Korean demand for Fiber to the Home (FTTH) installations.